What is a CNC Wood Router?

CNC Wood Router is a wood router machine controlled by the computer. It can process 2D/3D, milling, carving (relief, plane engraving, hollow carving, 3D carving), cutting, slotting and drilling of most popular wood materials and other soft materials, including woodworking crafts, wood carving, wooden marks, wooden toys, wooden gifts, cabinet making, wooden door making, wooden modelling, production of wooden furniture such as wardrobe.

The main structure of CNC Wood Router includes spindle, bed, gantry, servo motor and actuator, CNC operating system, CNC software, rack guide, screw, worktable, power supply, limit switch and so on.

CNC Wood Router is also known as wood CNC machine, woodworking CNC router, wood CNC router, CNC wood carving machine, wood CNC cutter, CNC wood milling machine, wood CNC table, CNC wood table, CNC wood router machine, CNC woodcarver, CNC wood engraver, CNC woodcutter, CNC wood cutting machine, c and c wood router, CNC woodworking machine, CNC wood engraver, wood c and c machine.

How does the CNC Wood Router work?

By using CAD or CAM software, the design and typesetting are carried out on the computer, and the generated information is automatically transmitted to the controller of the CNC wood router by the computer. Then the controller converts the information into a power signal (pulse train) which can drive the stepper motor or servo motor and controls the movement path of the X, Y and Z three axes of the CNC wood router host.

The high-speed spindle on the wood router machine, connected with the bits(cutting tools) suitable for processing the specified materials, then processing the material which fixed on the worktable, the parts designed in the computer will be processed by automatic processing.

CNC Wood Router includes 3-axis CNC Wood Router, 4-axis CNC Wood Router, 5-axis CNC Wood Router, and CNC machining centre with automatic tool changer.

How is a CNC Router used?

Common wood used for carpentry, furniture, and construction industries are:

Cork: commonly used in woodworking, construction and furniture industries, popular softwood wood such as pine, cedar, cedar, spruce, and mahogany.

Hardwood: usually there are beautiful and unique wooden patterns, used in handicrafts, decoration, and furniture industries, such as oak, maple, cherry, mahogany, walnut, bamboo, and palm.

Artificial wood: also known as composite boards, such as plywood, particleboard, MDF.

<1> Furniture making:

It produces all kinds of customized furniture, including doors and windows, beds, dining tables, chairs, staircases, windows, modern furniture, office furniture, and so on.

<2> Cabinet production:

Cabinet door, cabinet, shelf, curtain wall, and other integral cabinet production.

<3> Woodworking industry:

Three-dimensional wave plate processing, wooden musical instrument processing, decoration materials processing, decoration processing, etc.

<4> Mold industry:

It can engrave all kinds of effects, such as relief, shadow, engraving, plane carving, cutting, bottom washing, and so on.

<5> Advertising industry:

Advertising signs, PVC board, Teflon board, double colour plate, logo making, acrylic cutting, plastic moulding, big word cutting, sign production, cutting PVC, crystal board, acrylic, LED/ neon groove, hole type font cutting, Blister light box mould production.

<6> Crafts industry:

Pen, photo frame, pendulum, souvenir, custom gifts, vases, water cups, and other crafts and gifts processing.

<7> Foam carving:

Lost foam, large decorative items, handicrafts, and so on.

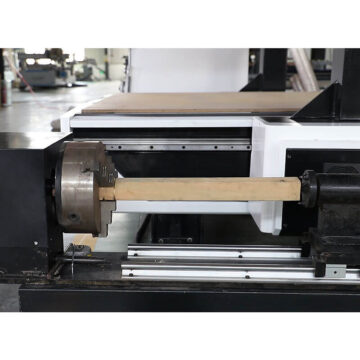

<8> Cylindrical engraving:

Table legs, dragon pillars, escalator posts, wooden railings, and so on.

What’s the worktable size of the CNC Router?

2×2, 2×3, 2×4, 4×4, 4×6, 4×8, 5×10 and 6×12 in feet;

16×16, 16×24, 24×24, 24×36, 24×48, 48×48, 48×96, 60×120, 80×120, and 80×160 in inch;

4040, 6040, 6060, 6090, 1212, 1218, 1224, 1325, 1530, 2030 and 2040 in milometer.

Of course, the worktable size can be customized as your requirements.

How to choose a suitable CNC Wood Router?

1. Working table size:

The dimension of the worktable is very important because it is related to the size of the raw material and/or the number of parts that must be cut in a certain time.

2. Spindle:

The spindle’s working mode and power are very important for the CNC milling machine. Generally, the spindle is divided into two parts. One is the water-cooled spindle and the other is the air-cooled spindle. The proper spindle is selected, depending on the temperature of your material and the weather in your country or region.

3. Cutting tools(CNC bits):

The selection of cutting tools(CNC bits) depends on the material and the process needed to be processed and is matched with the knife clamp and nut.

4. Control system:

Different axis numbers and processing materials correspond to different control systems. Reliability, effectiveness, stability, and user-friendliness should be considered.

5. Rack guide rail:

According to the material quality of processing parts, four factors, speed, stiffness, bearing capacity, and tool life, are considered.

6. Servo motor:

It is related to material quality, frequency, efficiency, load, and machining accuracy.

评论

发表评论